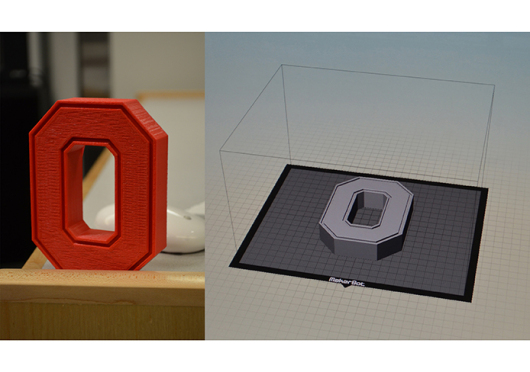

All OSU students, staff and faculty will have the opportunity to use 3-D printing for free at 2 different Digital Union locations on campus. Printing jobs to create various structures can be submitted through the Digital Union’s website. Credit: Robert Scarpinito / Lantern reporter

Students looking for a way to combine their technological and creative skills now have the means to do so using free three-dimensional printing services offered at two Digital Union locations on campus.

Three-dimensional printers are now housed in the Digital Union locations at Enarson Classroom 012 and Prior Hall 460a, and can be used by all students, staff and faculty, regardless of department affiliation, for no cost.

The 3-D printers are part of a pilot program the Digital Union is testing, which started on Jan. 12 and will continue until March 16. The two months are meant for data collection to see how viable the market is for 3-D printing at Ohio State, said Queenie Chow, manager of the Digital Union.

“That’s enough for us to assess things like cost, maintenance, types of jobs (and) demand,” Chow said. “Ultimately, this is our fact-finding mission to see who’s using it, what are they using it for and how useful it is.”

Anyone can submit a job through a form on the Digital Union’s website. The submission must include an STL (stereolithography) file, a type of file that contains the data for three-dimensional structures that computers can read.

Since the trial’s inception, more than 50 printing jobs have been done for various people, Chow said.

According to the 3-D printer queue on the Digital Union’s website, students have printed a variety of objects, ranging from a bottle opener to a mount for an ultrasonic circuit board.

Another student printed a smartphone microscope case, which snaps to the side of an iPhone 5S and holds a glass bead to magnify the camera by up to 1,000 times, Chow added.

Chow said the students who have used the printer so far come from a range of academic disciplines.

“The majority of our submissions have come from those who are from some area of engineering,” she said. “But there are definitely a lot of people from industrial design, from art and a lot of other departments, too.”

Even if someone does not have the skill set to design a 3-D model, the Digital Union offers assistance through Lynda, a service that teaches people how to use a variety of computer programs.

Each submission is reviewed by the Digital Union for dimensions because some 3-D models might be too tall or wide to fit in the printer and might need to be tweaked in size and structure. Intellectual property rights is also another criteria they look for.

“As long as it’s not a safety concern or a trademark concern, then your imagination is your only limit,” said Nathan Gammella, a student staff member at the Digital Union and a fifth-year in architecture.

An STL file can be created through computer-aided design programs, a list of which are on the Digital Union’s 3-D printing website. Examples include Rhinoceros 5, Mudbox, Blender and Maya.

The printers are both fifth generation MakerBot Replicators, each costing $2,899 according to the MakerBot website. Each large roll of filament, the material that the printer uses, starts at $48.

The Office of Distance Education and eLearning budgeted $10,000 to complete the pilot, Chow said in a follow-up email. The costs include the two 3-D printers, spare parts, filament, cabinets and cameras to capture the creations.

Funding for the pilot program comes from the Digital Union budget, Chow added.

CAD programs can be used to create models from scratch or modify pre-made models, which can be downloaded from Thingiverse, a website affiliated with MakerBot.

The 3-D printer works by having a base board that moves along a vertical z-axis under a heated extruder that releases the plastic across an x- and y-axis. The extruder heats up to 230 degrees Celsius, or 446 degrees Fahrenheit.

The material used at the Digital Union is PLA type plastic, which is extremely durable and easily malleable, Gammella said.

“You can model something and if it falls off your desk or has a high-impact (hit), it has great resistance,” he said.

The Digital Union has a selection of colored filaments to use, all of which are the same plastic dyed different shades. The online submission form allows the user to choose which color he or she wants the model to be printed in.

“When you submit your file, you have a (color) option and we will try to reach that option as long as we have that color in stock at the time,” Gammella said.

Finished products, however, don’t necessarily have to be the color of plastic they are printed in. They can be painted on using non-toxic water-based acrylic paint, which sticks to the material well, Gammella said.

Products must be picked up by the person who submitted the job with their BuckID used as verification. If items are not picked up in within seven days after printing, the Digital Union reserves the right to claim ownership of the item.

Chow said the Digital Union is not sure if it will continue the free printing services after the two-month test period.

“At this point, we can’t promise whether or not we’ll keep it after the pilot,” Chow said. “But the pilot is (going) to answer that question.”

As of Sunday afternoon, the queue for the printers was at more than 200 jobs.

Editor’s note: This article was updated with cost and budget information for the 3-D printers on Jan. 26.

Clarification Jan. 29, 2015

A previous version of this article contained a caption that incorrectly stated that students can 3-D print a block ‘O’ using the Digital Union 3-D printers, when in fact OSU symbols like the block ‘O’ cannot be printed because of Trademark and Licensing legalities.